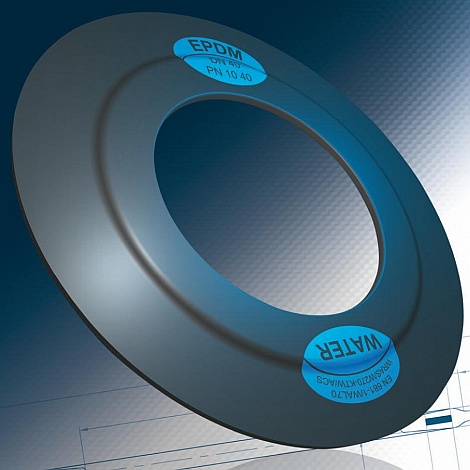

Industrial seals and insulation materials

We are a manufacturer of industrial seals and insulation in the Czech Republic and Slovakia. We perform custom production in pieces and in large series.

Popular categories

Customised production

We are able to quickly respond to customer needs in the field of industrial insulation and sealing. Our software equipment allows us to transfer drawing documentation directly to the control systems of production machines.

About company

The company Ruml Tesnění was founded in May 2011. After modifications to the production and warehouse premises and the installation of the first machine, the company started production in July 2011.

The company now has approximately 1,000 m2 of production space and the necessary background for flexible production at the Bonega company premises in Sudoměřice nad Moravou. In addition to the production of seals from various materials, the company is engaged in the sale of a wide range of seals, industrial insulation and connecting material.

References

Do you want to work with us?

We offer the opportunity to work in the dynamically developing RUML GROUP group of companies.